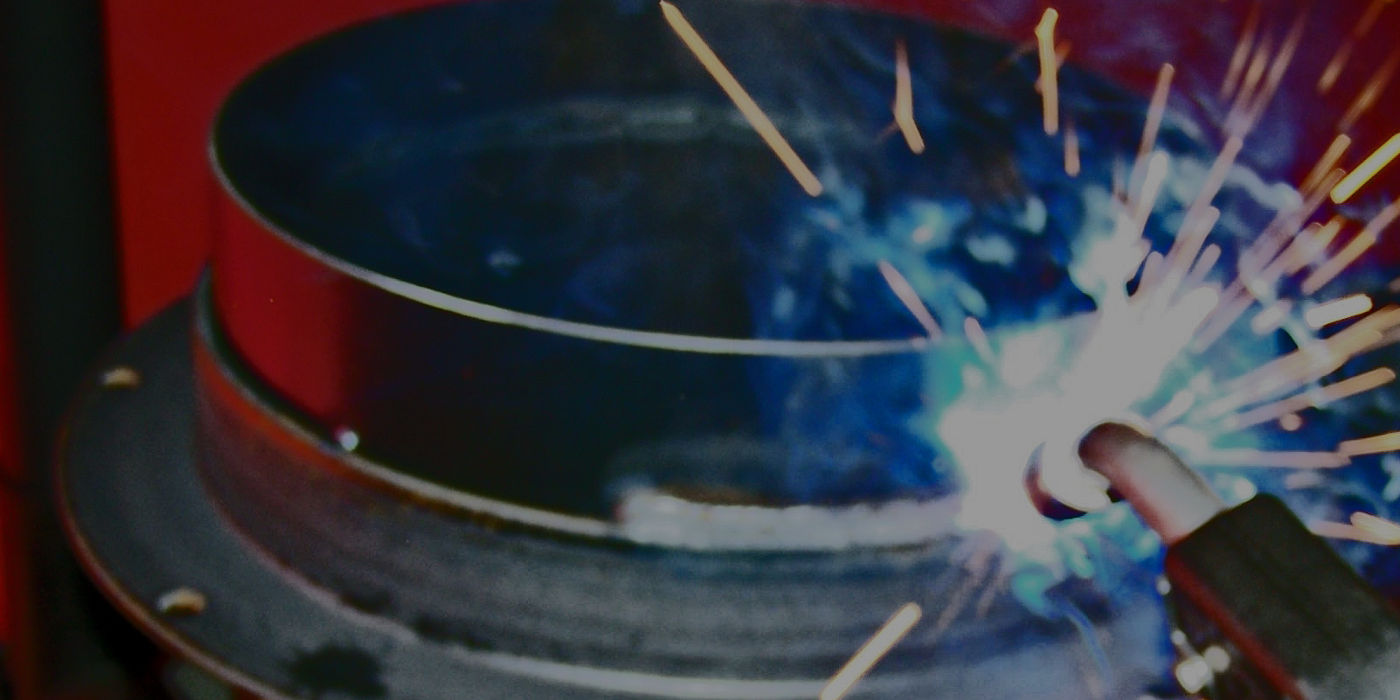

There has always been something artistic about welding. The process of placing two pieces of metal together, heating and molding them to create one combined part, no weaker than before, will always be somewhat of an art form. The DME welding artistry performed on a daily basis is mind-blowing to say the least. The experienced welders and sophisticated equipment are unmatched in the industry.

A large portion of the material welded at DME is stainless steel. In welding stainless steel, DME welders must pay careful attention to the material being welded so not to overheat the parts and create a warped or unreliable finished product. DME has taken several steps to make sure this does not happen, and still produce parts in a high quality, timely manner.

One of the ways DME has improved its welding procedures is by the utilization of highly advanced pulse MIG welders. These machines produce high deposition welds with far less heat than standard MIG welders or TIG welders. These machines can actually produce the same components in half the time of conventional methods. What does this mean for the DME customer? It means DME can manufacture expansion joints faster, more precise, and with the same quality DME has been known for.

Another type of welder DME utilizes day in and day out, is the extremely precise longitudinal seam welder, fitted for either TIG welding or state of the art plasma welding technology. At DME all of our metal bellows are seam welded in house, giving the customer the satisfaction and guarantee it will be manufactured correctly, the first time.

The welders at DME are only a small part of the dedication placed on Quality and Customer Satisfaction. DME has become the leader in quality expansion joints, so Contact a Product Specialist today.